Introducing laser surface preparation systems at FMF Cape Breton

By Lookout Production on Jul 20, 2023 with Comments 0

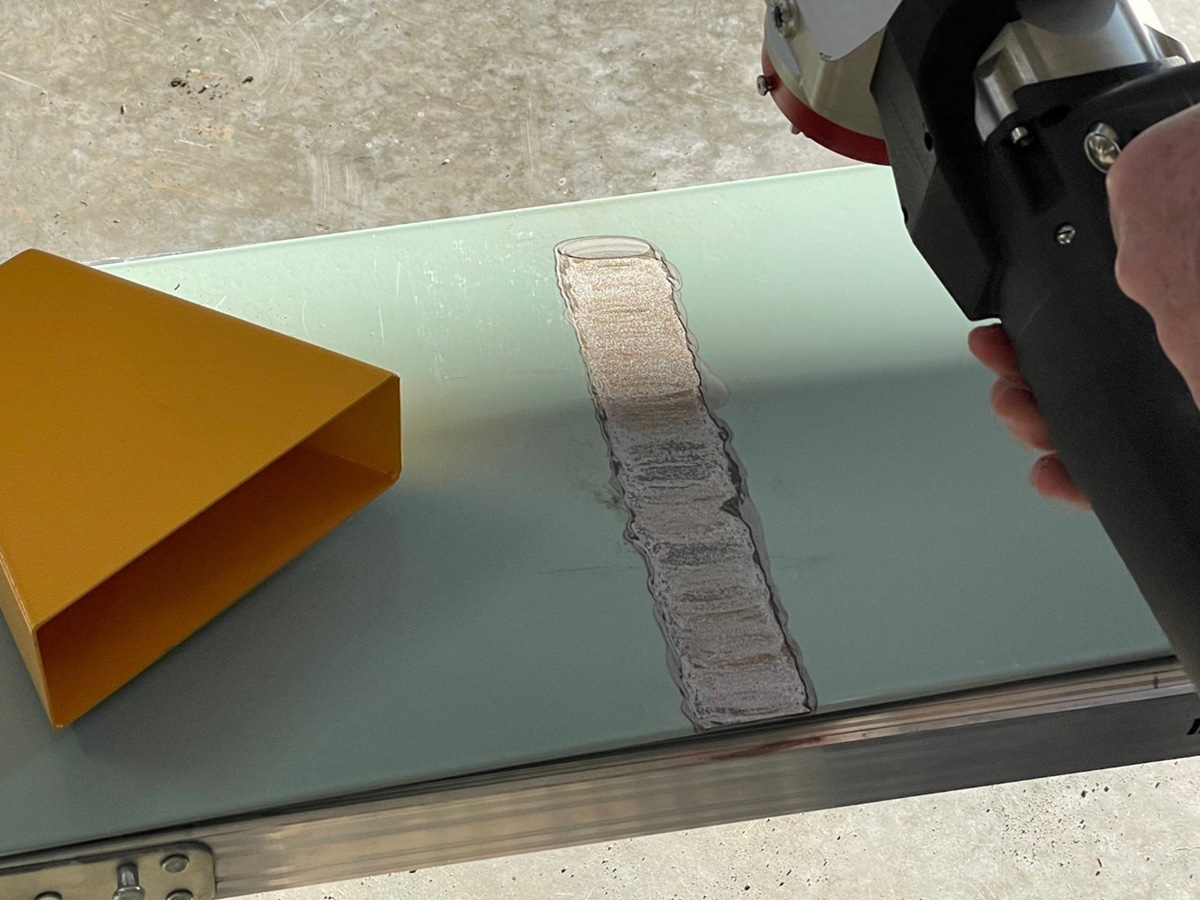

The new laser will prepare surfaces for cleaning and repainting. Photo supplied

Gabrielle Brunette

FMF Cape Scott

Alan McNaul, Work Center Manager Group 1, has been working hard to establish new capabilities for the Fleet Maintenance Facility Cape Breton (FMF CB).

His latest goal is to introduce Laser Surface Preparation Systems.

“The equipment represents a technology long used in the medical field but only recently adapted for more industrial types of surface cleaning and preparation,” McNaul said.

While FMF Cape Scott (FMF CS) in Halifax has also purchased the equipment, Cape Breton would be the first to see it implemented. It will replace high-impact tooling, which can damage substrates and affect workers’ health and well-being.

McNaul explains the P-Laser 1000-Watt unit is a laser device used to surgically remove tissue to create a clean, paintable surface or one suitable for inspection. The technology can be used on most materials, although McNaul notes it is most effective on thinner coatings and corrosion.

The equipment was purchased three years ago but underwent long testing and approval processes to be deemed safe to bring into service.

“As it is new and has had relatively little research conducted, we had to address a few laser safety and respiratory health and safety concerns before implementing it within the Department of National Defence (DND),” McNaul said.

Multiple organizations need to be satisfied with the safety of the laser, given its designation as a Class 4 laser device – the highest rating according to the International Electrotechnical Commission (IEC) standards. McNaul worked closely with the National Defence Laser Safety, Director of Force Health Protection, DND Preventive Medicine, and all internal FMF Safety and Health agents. He also contracted external health and safety testing laboratories.

Once the equipment is ready, it will be packed into containers for placement on the upper decks of the ships.

McNaul and other agencies in DND have put approximately 1,500 hours of work into getting these devices approved to go onto the vessels, with about 400 more hours of work left. He hopes the project will be completed within the year.

McNaul said the work he has put into implementing this device has been gratifying.

“The new technology will benefit not only FMF CB and FMF CS, but also the larger DND/CAF community across all elements,” he said.

Filed Under: Featured

About the Author: